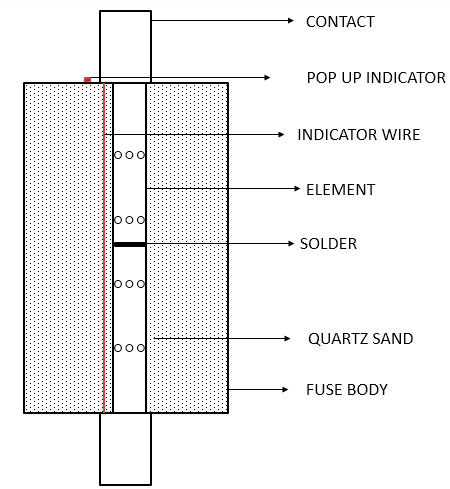

Fuse is a device that blows in case of a fault & can offer protection up to 80KA even beyond that. Whenever there is a fault in the system the fuse blows off & protects the system by cutting off the supply. A fuse is generally made of a ceramic body, having an element, The body is filled with quartz sand as shown in the fig:

Whenever there is an overload in the system, the solder as shown gets into a chemical reaction resulting in cutting off the supply. In the case of a short circuit, the element gets torn due to the application of high electrodynamic force on the same because of high current such as a short circuit. The blown fuse can be easily identified by the pop up indicator which pops up whenever the fuse interrupts. The function of quartz sand is to successfully quench the arc & absorb the pressure thus, not letting the fuse to explode. The fuse is the staunchest combatant of the system as it is the quickest interrupting device available in the entire electrical system. The fuse blown within 2-5ms hence saving the maximum amount of let-through energy.

Fuse can be identified as mentioned below:

The first letter is ‘a’ if the fuse is for short-circuit protection only; an associated device must provide overload protection.

The first letter is ‘g’ if the fuse is intended to operate even with currents as low as those that cause it to blow in one hour, ex. Overload. These are considered general-purpose fuses for the protection of wires.

The second letter indicates the type of equipment or system to be protected:

G – General purpose protection of wires and cables

M – Motors

PV – Solar photovoltaic arrays as per 60269-6

R, S – Rectifiers or semiconductors as per 60269-5

Tr – Transformers

Fuse although, is the most dependable & trusted protection device but can be used only one time, in no case the fuse can be repaired after it blows off it only needs to be replaced.

No comments:

Post a Comment